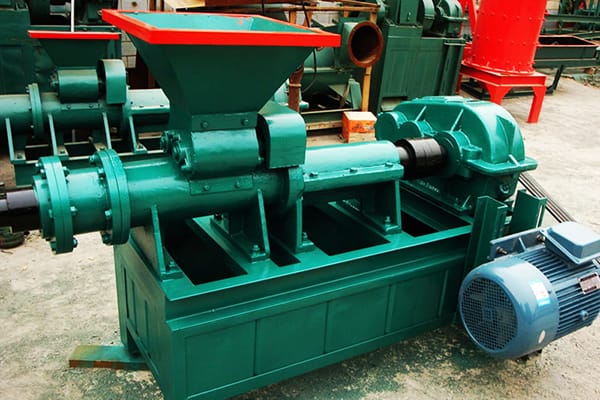

The feeding part is mainly used to achieve ration feeding so as to ensure that the materials can be fed into the rollers uniformly. Specifically, the screw feeder, driven by electromagnetic speed-adjustable motor, presses materials into the main feeding port compulsively by means of the belt pulley and worm reducer. Owing to constant torque, the motor can keep constant feeding pressure, ensuring stable briquette quality.

The main drive system of the briquetting machine is composed of motor, triangle belt, reducer, exposed gear and rollers. The power generated by the electromagnetic speed-adjustable motor transmits to the driving shaft through belt pulley, reducer and coupler, and the driving shaft will turn synchronously with the driven shaft by the exposed gear.

The core of the briquette molding part is the rollers. Through rollers, the raw materials can be compressed into briquettes with various shapes. In addition, the rollers feature overload protection, hence keeping sound quality.

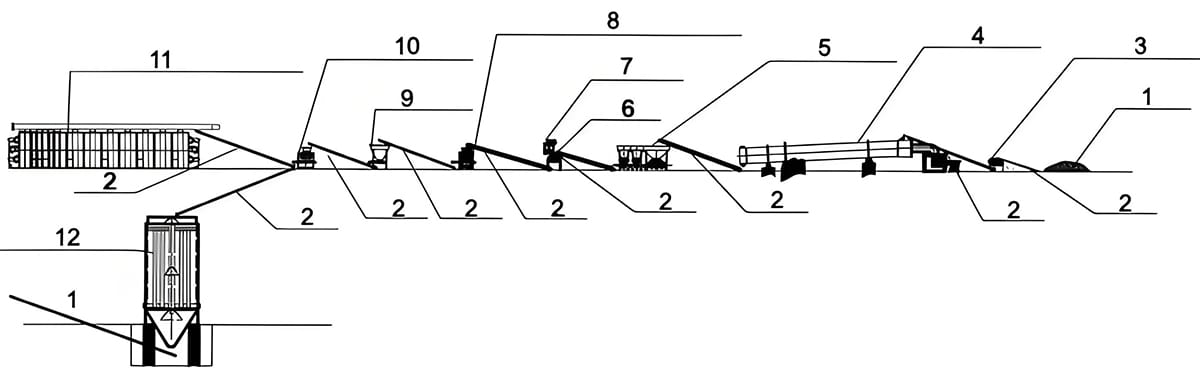

Notes: This flow chart can be also designed based on customers'actual demand.

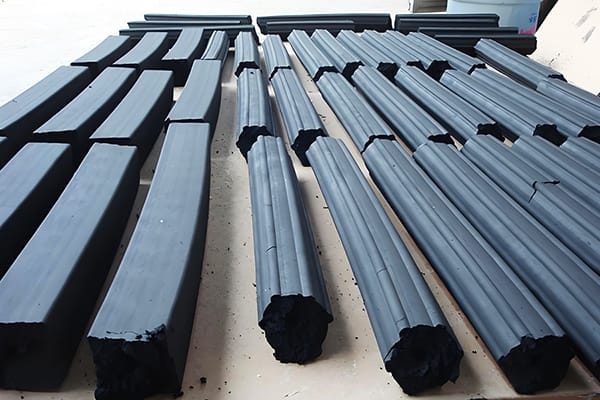

This briquette forming machine can turn raw materials into pellets that are convenient for transportation, thus improving utilization ratio of waste materials and bringing excellent economic benefit and social benefit. The shape of the finished products made by this briquetting machine is various and can be customized.

The industrial briquetting machinery has won great popularity and recognition among large and medium-size enterprises in the world. It can not only save a large amount of resource consumption and economic cost, but also play a critical role in developing circular economy. Hence, it is an energy saving and environment friendly equipment.

The tolerance clearance refers to the gap between the screw rod (spiral spindle) and the sleeve in mechanical briquetting machines. This clearance allows the material to be compacted under high temperature and pressure. As the material moves between the screw rod and the sleeve, it is squeezed into the desired shape. The precision of this clearance is crucial for producing high-quality briquettes.

The production capacity varies based on the briquette size (finished ball size) and the material's density.

Yes, raw materials must be properly prepared for briquetting. They should be dry (8-12% moisture content), free of foreign objects (stones, metals), and within the machine's specified size range.

We design production line processes based on customer’s site conditions, ensuring optimal equipment placement. We provide detailed equipment dimensions and layout diagrams. Upon arrival, customers can arrange the equipment according to our provided plans. We also offer comprehensive operating procedures and process flow instructions for each machine. Our team provides phone and video technical support for any installation or troubleshooting needs.

Yes, we offer on-site technical support as needed. Our engineers have extensive global experience, serving clients in countries like Bahrain, Oman, Iran, India, Thailand, Australia, Russia, Mongolia, Bangladesh, Cote d'Ivoire, and Mexico, among others

YUKE specializes in providing high-efficiency and energy-saving briquetting machine and production line solutions. Our automated production lines are versatile and essential for material forming across various industries. We offer complete production line equipment, including vibrating screens, crushers, batching machines, dryers, mixers, briquetting machines, feeders, and conveyors, forming a comprehensive material processing system. Our core briquetting machines are designed to efficiently compress a wide range of powdered materials, such as iron powder, mineral powder, oxide scale, and refractory materials, catering to the metallurgical, chemical, and construction industries.

Our mineral briquette production line high-pressure compresses various mineral powders, including iron powder, aluminum powder, bauxite, phosphate powder, and magnesium powder, into diverse shapes. The resulting briquettes can be dried or air-dried.

This line comprises silos, belt conveyors, mixers, binder feeders, briquetting machines, and dryers. Ideal for metallurgy and casting, our designs are customized to meet specific client needs. With successful installations in China, Bahrain, Russia, India, Indonesia, Iran, and Oman, our production lines are known for their reliability and performance.

The coal briquette production line high-pressure compresses coal powder and coal slurry for use in civil heating, power plant generation, and boiler fuel. This line includes crushers, silos, belt conveyors, mixers, binder feeders, briquetting machines, and dryers.

We provide customized designs to suit client specifications. Our coal briquetting lines are operational in China, Poland, Russia, India, Indonesia, South Africa, Cote d'Ivoire, Tanzania, and Mongolia, delivering consistent performance and client satisfaction.

The lime briquette production line high-pressure compresses lime powder without additional binders. This line features silos, conveyors, and high-pressure dry powder briquetting machines. We offer tailored designs to meet client requirements.

Our lime briquetting lines are successfully used in China, Australia, India, and Thailand, delivering reliable and efficient performance.

The oxide scale briquette production line high-pressure compresses oxide scale, steel mill dust, iron powder, and steel powder for metallurgical applications. This line includes crushers, silos, belt conveyors, mixers, binder feeders, briquetting machines, dryers, and dust collectors.

We provide customized designs for optimal performance. Our oxide scale briquetting lines are operational in China, Bahrain, Russia, India, Indonesia, Iran, and Oman, delivering consistent results and client satisfaction.

Our team will help you design and customize a briquetting system that fits your material, capacity, and site conditions.