YUKE hydraulic briquetting press is entirely manufactured from steel casting instead of steel plate weld assembly, eradicating cracking problem and improving stability and service life.

Advanced hydraulic drive technology, superposition and combination valves, superior wear resistant oil seal and specially constructed oil cylinder by up-to-the-minute technology keep continuous operation with full power and stability.

The metal powder forming press boasts computer control system which contributes to high automation, low failure rate and easy maintenance.

Automatic screw feeder and chain discharging device can be equipped based on user's condition.

YUKE hydraulic briquetting press has been approved by National Quality Supervision Bureau and obtained certificates of ISO9001, CE, GOST, etc. Furthermore, we have applied for many patents for this metal briquette forming equipment. YUKE has won great popularity in briquette press industry.

The production capacity varies based on the briquette size (finished ball size) and the material's density.

A general term for machines that compress materials (biomass, coal, metal fines) into briquettes using mechanical force. Finished briquette shapes include flat circular, elliptical, pillow-shaped, and granular, with custom mold options available.

A specific type of briquetting machine that uses hydraulic pressure for compression, offering greater control and higher pressure for denser briquettes. Finished briquette shapes include flat cylindrical, rectangular, cubic, pie-shaped, and brick-shaped, with custom mold options.

Yes, raw materials must be properly prepared for briquetting. They should be dry (8-12% moisture content), free of foreign objects (stones, metals), and within the machine's specified size range.

We design production line processes based on customer’s site conditions, ensuring optimal equipment placement. We provide detailed equipment dimensions and layout diagrams. Upon arrival, customers can arrange the equipment according to our provided plans. We also offer comprehensive operating procedures and process flow instructions for each machine. Our team provides phone and video technical support for any installation or troubleshooting needs.

Yes, we offer on-site technical support as needed. Our engineers have extensive global experience, serving clients in countries like Bahrain, Oman, Iran, India, Thailand, Australia, Russia, Mongolia, Bangladesh, Cote d'Ivoire, and Mexico, among others

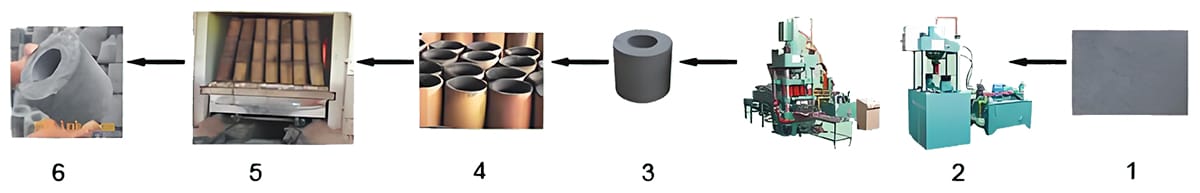

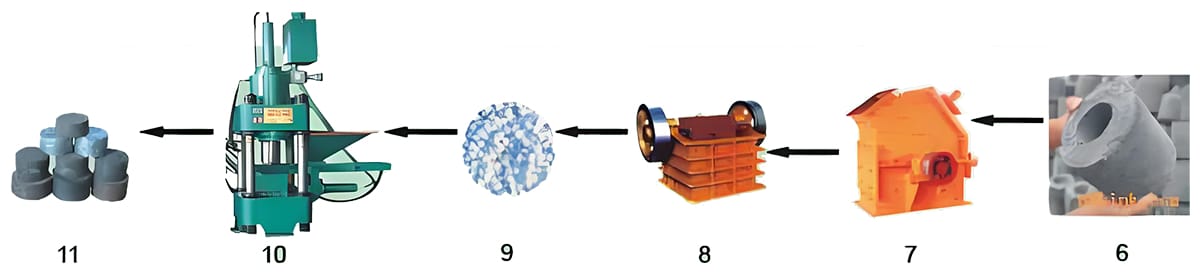

YUKE specializes in providing high-efficiency and energy-saving briquetting machine and production line solutions. Our automated production lines are versatile and essential for material forming across various industries. We offer complete production line equipment, including vibrating screens, crushers, batching machines, dryers, mixers, briquetting machines, feeders, and conveyors, forming a comprehensive material processing system. Our core briquetting machines are designed to efficiently compress a wide range of powdered materials, such as iron powder, mineral powder, oxide scale, and refractory materials, catering to the metallurgical, chemical, and construction industries.

Our mineral briquette production line high-pressure compresses various mineral powders, including iron powder, aluminum powder, bauxite, phosphate powder, and magnesium powder, into diverse shapes. The resulting briquettes can be dried or air-dried.

This line comprises silos, belt conveyors, mixers, binder feeders, briquetting machines, and dryers. Ideal for metallurgy and casting, our designs are customized to meet specific client needs. With successful installations in China, Bahrain, Russia, India, Indonesia, Iran, and Oman, our production lines are known for their reliability and performance.

The coal briquette production line high-pressure compresses coal powder and coal slurry for use in civil heating, power plant generation, and boiler fuel. This line includes crushers, silos, belt conveyors, mixers, binder feeders, briquetting machines, and dryers.

We provide customized designs to suit client specifications. Our coal briquetting lines are operational in China, Poland, Russia, India, Indonesia, South Africa, Cote d'Ivoire, Tanzania, and Mongolia, delivering consistent performance and client satisfaction.

The lime briquette production line high-pressure compresses lime powder without additional binders. This line features silos, conveyors, and high-pressure dry powder briquetting machines. We offer tailored designs to meet client requirements.

Our lime briquetting lines are successfully used in China, Australia, India, and Thailand, delivering reliable and efficient performance.

The oxide scale briquette production line high-pressure compresses oxide scale, steel mill dust, iron powder, and steel powder for metallurgical applications. This line includes crushers, silos, belt conveyors, mixers, binder feeders, briquetting machines, dryers, and dust collectors.

We provide customized designs for optimal performance. Our oxide scale briquetting lines are operational in China, Bahrain, Russia, India, Indonesia, Iran, and Oman, delivering consistent results and client satisfaction.

Our team will help you design and customize a briquetting system that fits your material, capacity, and site conditions.