The drum dryer for animal manure is proud of extremely high safety.

This rotary drum dryer slopes slightly so that the discharge end is lower than the material feed end.

This drum drying equipment can precisely take material fineness and moisture under control as per requirements of customer.

The drum dryer for gypsum can be used for drying flue gas desulfurization (hereinafter referred to as FGD) gypsum and precisely reduce moisture content to the standard required by customer.

Drying plays a essential role during the process of iron powder briquetting.

The drum dryer for coal is mainly used to dry the raw coal with 20%-40% moisture content, and the dried coal can be used for power generating, home heating, blast furnace smelting, etc.

Our drum dryer for sand has been widely recognized by domestic and overseas enterprises.

The wood chip is a kind of organic matter with 20%-40% moisture content.

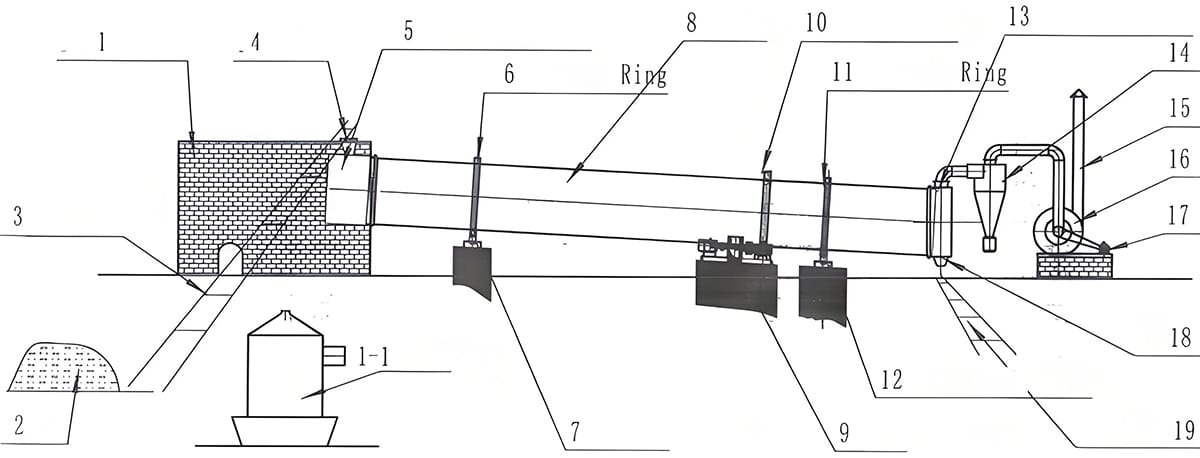

The wet stock will be firstly conveyed to the hopper by belt conveyor or bucket elevator. Then, the materials will be fed into the feed end through feeding pipe. The slope angle of the feeding pipe is bigger than the natural angle of the material so that they can smoothly flow into the dryer drum.

The rotary drum slopes slightly. The materials fed into the drum from the higher end (feed end) will countercurrent contact with the heating carrying agent (heated gas or flue gas) blew into the drum from the lower end (discharge end). There is another situation that the material and heated gas enter the drum together from the lower end and implement co-current flow contact.

Before moving through the dryer drum, the heat-carrying gas will be processed by cyclone dust collector to separate the material blended in the gas. In addition, bag filter or dust washer can be used to further reduce dust content in the gas.

Notes: This flow chart can be also designed based on customers'actual demand.

Our team will help you design and customize a briquetting system that fits your material, capacity, and site conditions.