The coke briquetting machine is specially designed by YUKE for maximizing the value of fine coke and coke breeze produced in coking. In actual processing, this coke briquetting equipment compresses the coke powder and coke breeze into briquettes with various forms. Owing to many superiorities such as large pressure, stable performance, high briquetting efficiency, etc. YUKE coke briquette making machine can produce the most premium coke pellets which boast high intensity and are unbreakable during transporting or burning. In addition, this industrial waste processing equipment is energy saving and environment friendly.

The coke briquetting machine has found wide application in iron making, non-ferrous metal smelting, casting, etc. It has been exported to a number of countries around the globe, including UAE, south Africa, Brazil, India, Malaysia, Indonesia, to name a few.

| Model | Roll Diameter(mm) | Capacity(t/h) | Power(kw) | Briquettes Shape and Size |

| YKBM290 | 290 | 1-3 | 5.5 | Defined by users |

| YKBM360 | 360 | 4-6 | 11-15 | Defined by users |

| YKBM430 | 430 | 6-8 | 18.5 | Defined by users |

| YKBM500 | 500 | 8-12 | 18.5-55 | Defined by users |

| YKBM500H | 500 | 8-12 | 18.5-55 | Defined by users |

| YKBM650 | 650 | 10-15 | 37-45 | Defined by users |

| YKBM650H | 650 | 10-15 | 37-45 | Defined by users |

| YKBM750 | 750 | 15-20 | 75-110 | Defined by users |

| YKBM750H | 750 | 15-20 | 75-110 | Defined by users |

| YKBM850 | 850 | 20-25 | 90-110 | Defined by users |

| YKBM850H | 850 | 20-25 | 90-110 | Defined by users |

| YKBM1000 | 1000 | 25-35 | 90-132 | Defined by users |

| YKBM1000H | 1000 | 25-35 | 90-132 | Defined by users |

Note: Above technical parameters are for reference and can be separately designed according to customer's actual situation. In addition, above briquetting machines can be separately equipped with hydraulic system.

YUKE briquetting machine consists of three parts, namely feeding part, drive part and briquette molding part (main body).

The feeding part is mainly used to achieve ration feeding so as to ensure that the materials can be fed into the rollers uniformly. Specifically, the screw feeder, driven by electromagnetic speed-adjustable motor, presses materials into the main feeding port compulsively by means of the belt pulley and worm reducer. Owing to constant torque, the motor can keep constant feeding pressure, ensuring stable briquette quality.

The main drive system of the briquetting machine is composed of motor, triangle belt, reducer, exposed gear and rollers. The power generated by the electromagnetic speed-adjustable motor transmits to the driving shaft through belt pulley, reducer and coupler, and the driving shaft will turn synchronously with the driven shaft by the exposed gear.

The core of the briquette molding part is the rollers. Through rollers, the raw materials can be compressed into briquettes with various shapes. In addition, the rollers feature overload protection, hence keeping sound quality.

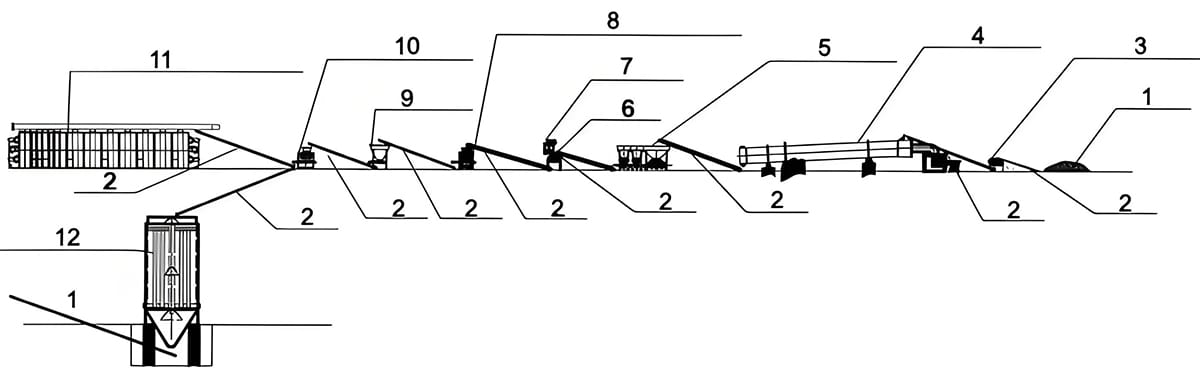

Notes: This flow chart can be also designed based on customers'actual demand.

Looking for Briquetting Machines That Fit Your Requirements?

Whether it’s metal, sludge, biomass, or coal, we design the right briquetting solution for your needs.

YUKE specializes in providing high-efficiency and energy-saving briquetting machine and production line solutions. Our automated production lines are versatile and essential for material forming across various industries. We offer complete production line equipment, including vibrating screens, crushers, batching machines, dryers, mixers, briquetting machines, feeders, and conveyors, forming a comprehensive material processing system. Our core briquetting machines are designed to efficiently compress a wide range of powdered materials, such as iron powder, mineral powder, oxide scale, and refractory materials, catering to the metallurgical, chemical, and construction industries.