The drum dryer for gypsum can be used for drying flue gas desulfurization (hereinafter referred to as FGD) gypsum and precisely reduce moisture content to the standard required by customer. It is a kind of great drying equipment developed for continuously processing large bulks of material. The dried FGD gypsum produced by this gypsum rotary dryer can be used as cement retarder or calcined into semi-hydrated gypsum that is utilized to make gypsum board, gypsum block and gypsum plaster.

YUKE gypsum drum drying machine, boasting outstanding drying effect to FGD gypsum, phosphorous gypsum, natural gypsum, etc. is widely used in the fields of cement, building materials, chemical and others. The materials dried by the drum dryer for gypsum can be recycled, thus ensuring low energy consumption and low environmental pollution.

| Model | Gradient(%) | Diameter (mm) | Length(mm) | Speed(r/min) | Rotary Power(kw) | Capacity(t/h) | Weigh(t) |

| YKRD0606 | 3-5 | 600 | 6000 | 3-8 | 3 | 0.5-1.5 | 2.9 |

| YKRD0608 | 3-5 | 600 | 8000 | 3-8 | 4 | 0.6-1.2 | 3.1 |

| YKRD0808 | 3-5 | 800 | 8000 | 3-8 | 4 | 0.8-2.0 | 3.5 |

| YKRD0810 | 3-5 | 1000 | 8000 | 3-8 | 4 | 0.8-2.5 | 5.6 |

| YKRD1010 | 3-5 | 1000 | 10000 | 3-8 | 5.5 | 1.0-3.5 | 6.7 |

| YKRD1012 | 3-5 | 1000 | 12000 | 3-8 | 5.5 | 1.5-3.5 | 7.2 |

| YKRD1208 | 3-5 | 1200 | 8000 | 3-8 | 7.5 | 2-4 | 8.8 |

| YKRD1210 | 3-5 | 1200 | 10000 | 3-8 | 7.5 | 1.8-5 | 9.8 |

| YKRD1212 | 3-5 | 1200 | 12000 | 3-8 | 11 | 2-6 | 10.5 |

| YKRD1512 | 3-5 | 1500 | 12000 | 2-6 | 15 | 3.5-9 | 13.5 |

| YKRD1514 | 3-5 | 1500 | 14000 | 2-6 | 15 | 4-11 | 15.4 |

| YKRD1812 | 3-5 | 1800 | 12000 | 2-6 | 18.5 | 5-12 | 18.9 |

| YKRD1814 | 3-5 | 1800 | 14000 | 2-6 | 18.5 | 5-15 | 23.2 |

| YKRD1820 | 3-5 | 1800 | 20000 | 2-6 | 22 | 8-20 | 26.1 |

| YKRD2018 | 3-5 | 2000 | 18000 | 2-6 | 30 | 8-23 | 36.5 |

| YKRD2020 | 3-5 | 2000 | 20000 | 2-6 | 37 | 10-24 | 38.8 |

| YKRD2218 | 3-5 | 2200 | 18000 | 1.5-6 | 37 | 10-25 | 42.3 |

| YKRD2220 | 3-5 | 2200 | 20000 | 1.5-6 | 37 | 12-28 | 45.2 |

| YKRD2420 | 3-5 | 2400 | 20000 | 1.5-5 | 45 | 18-30 | 50.7 |

| YKRD2820 | 3-5 | 2800 | 20000 | 1.5-5 | 55 | 20-35 | 60.4 |

| YKRD2824 | 3-5 | 2800 | 24000 | 1.5-5 | 75 | 25-35 | 70.4 |

| YKRD3020 | 3-5 | 3000 | 20000 | 1.5-5 | 75 | 25-40 | 78.2 |

| YKRD3025 | 3-5 | 3000 | 25000 | 1.5-5 | 75 | 30-45 | 104.9 |

Note: Above technical parameters are for reference,can be separately designed according to customer’s actual situation.

How does YUKE Drum Dryer Work?

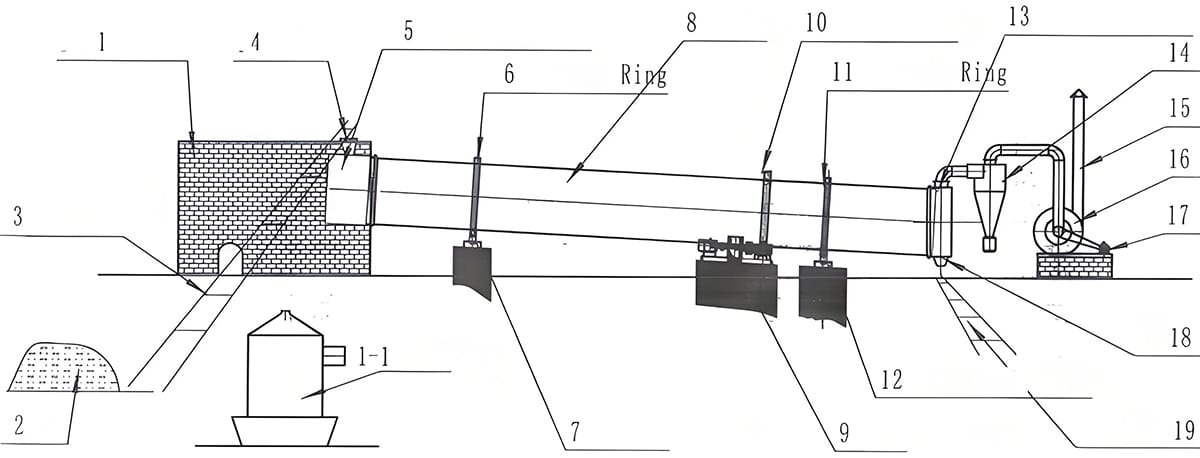

The wet stock will be firstly conveyed to the hopper by belt conveyor or bucket elevator. Then, the materials will be fed into the feed end through feeding pipe. The slope angle of the feeding pipe is bigger than the natural angle of the material so that they can smoothly flow into the dryer drum.

The rotary drum slopes slightly. The materials fed into the drum from the higher end (feed end) will countercurrent contact with the heating carrying agent (heated gas or flue gas) blew into the drum from the lower end (discharge end). There is another situation that the material and heated gas enter the drum together from the lower end and implement co-current flow contact.

As the drum rotates, the material will move toward lower end under gravity. During the moving process, the material will be heated and dried directly or indirectly by the heat-carrying gas, and then conveyed out of the drum by belt conveyor or screw conveyor.

Specially, lifting plates are mounted on the internal wall, for the purpose of lifting the materials and scattering them, enabling the materials to fully contact with the heated gas so as to accelerate drying rate and facilitate material moving.

Before moving through the dryer drum, the heat-carrying gas will be processed by cyclone dust collector to separate the material blended in the gas. In addition, bag filter or dust washer can be used to further reduce dust content in the gas.

Looking for Briquetting Machines That Fit Your Requirements?

Whether it’s metal, sludge, biomass, or coal, we design the right briquetting solution for your needs.